JTEKT OP Supporter Software

A system on JTEKT Machinery machining centers which gives automation functionalities on the machines. Delivering high-end features for a wide range of production and job shop environments, the OP Supporter provides a wealth of preventative maintenance information displayed on the CNC screen. There are 3 supporting features of OP Supporter: tool control support, pallet control support, and maintenance control support.

Tool Control Support

- Simple program - Tool number conversion function

- Detailed control - Tool life control function

- Direct tool setting capability - Tool offset function

- Tool teaching - Tool list display function

- Limiting arm speed according to tool weight - ATC speed variation function

- Faulty tool indexing - Replacement tool automatic indexing function

- Manual tool data entry not required - Tool ID Function

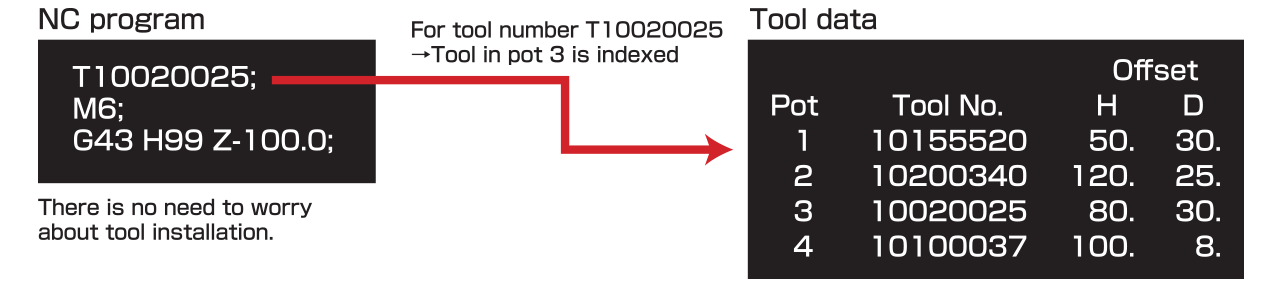

Simple NC Program Creation

Tool number conversion function: Tool identification number is automatically converted into the ATC magazine pot number, preventing command errors.

Simple Registration of Tool Data

Tool ID function: The ID chip containing tool data (correction data, tool life, AC data, machining condition, etc.) eliminates manual tool data entry and human error.

Accurate Tool Life Appraisal

Tool life control function: A counting method giving readings at 0.1 sec accuracy. Provides a double-layered fault warning system that generates warning of actual error. Tool breakages and AC faults are displayed in addition to tool life.

Preliminary Tool Check

Program tool check function: The tools used in the program are analyzed and any tool shortages are notified.

TOYOPUC-TOUCH HMI Tool Management Function

- Allows automatic indexing of the selected pot without having to know the tool installation position

- Protects tools by using ATC speed commands suited to each tool

- Enables prior assessment of abnormal or insufficient tooling

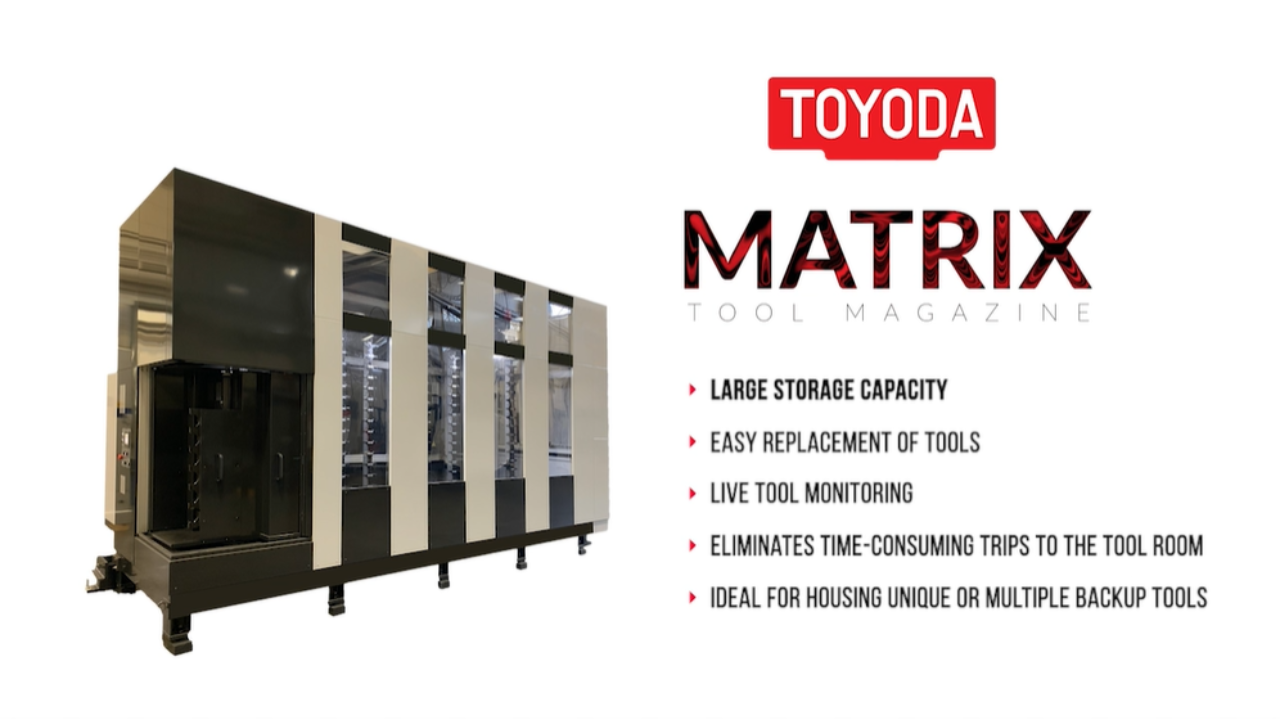

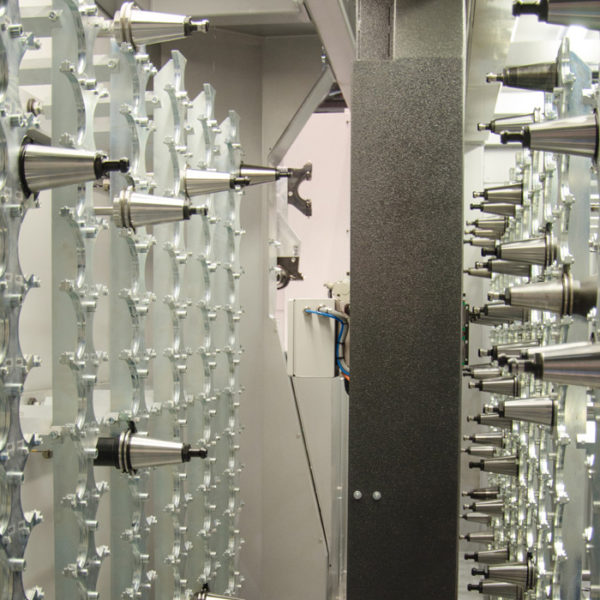

Matrix Tool Magazine

JTEKT's matrix tool magazines are large capacity, stationary tool storage racks. These add-ons allow JTEKT horizontal machining centers to be tooled for more part numbers, eliminating time-consuming trips to the tool room.

Compact Matrix Magazine

The compact tool magazine is an auxiliary tool storage unit ideal for housing unique tools or multiple backup tools used during unmanned machining. JTEKT's compact matrix magazine is capable of holding up to 180 tools (50 taper) and up to 304 tools (40 taper). Custom configurations are available.

Matrix Magazine

JTEKT's matrix tool magazine is a large capacity, auxiliary tool storage rack that accommodates up to 504 tools. Ideal for workpieces requiring many unique tools or redundant tools, the matrix magazine eliminates unnecessary trips to the tool room.

Large Storage Capacity

The magazine not only supplies a greater variety of tools to a machine, but it allows operators to store redundant tools for lights-out production and fewer trips to the tool room.

Easy Replacement of Tools

Up to a five-tool loading station ties into the control system so operators can replace worn and damaged tools without interrupting scheduled magazine operations.

Live Tool Monitoring

All matrix magazines offer JTEKT's live tool monitoring software. It works dynamically, automatically detecting broken and worn tools and bringing them to the unloading station. This system monitors the specifications and life of every tool in operation, making it easy for the operator to manage the inventory of tools in the machine.

Matrix Tool Magazine

Matrix tool magazines are large capacity, stationary tool storage racks