Solving a Critical Parts Challenge

Manufacturers need a reliable supply of CNC machined parts. "This is best achieved when the foundry, machine shop and customer form a stron…

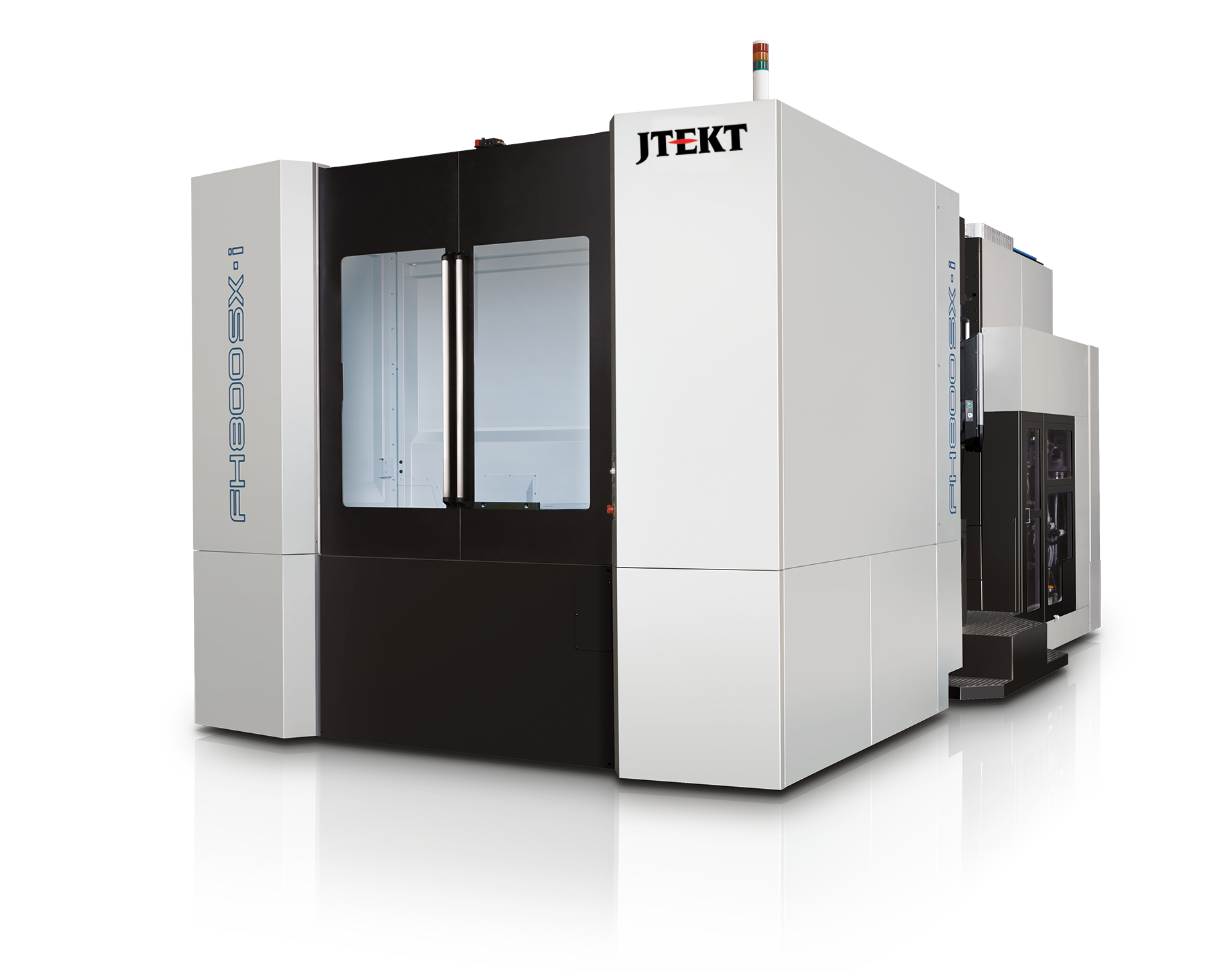

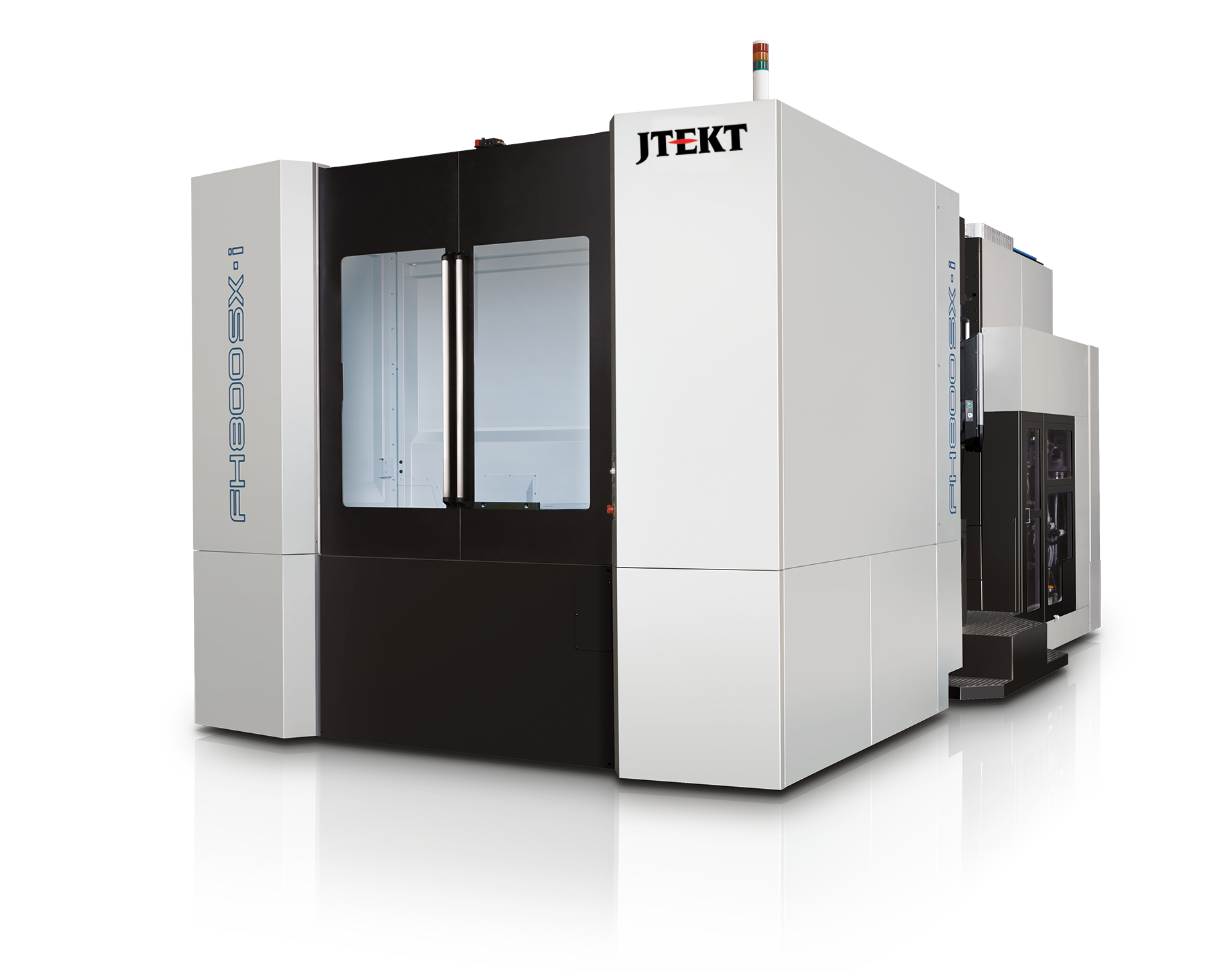

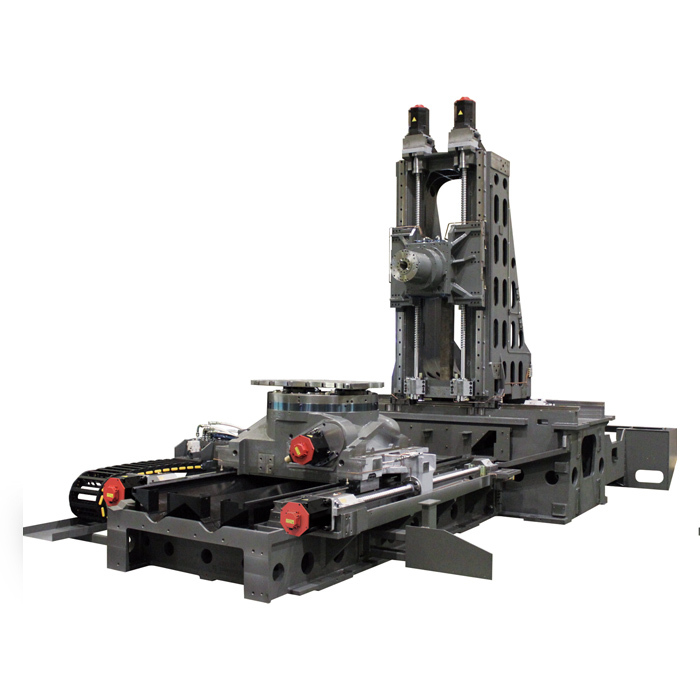

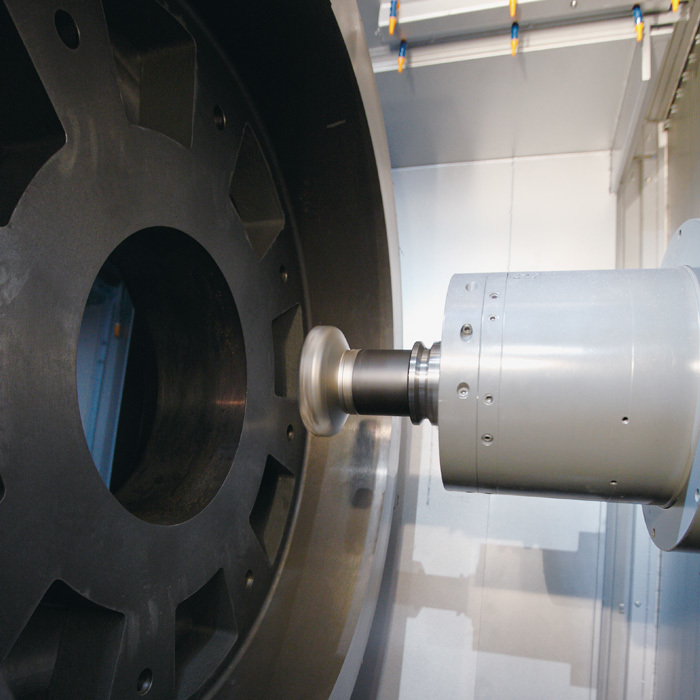

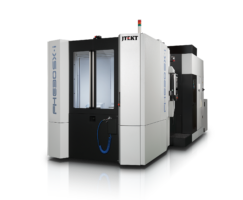

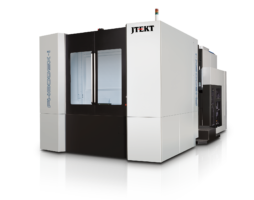

The FH800SX-i is a powerful, high-speed horizontal machining center featuring a 6,000 RPM spindle, with options of an 8,000 RPM or 15,000 RPM high-torque spindle, and a rapid feedrate of 2,127 ipm (54 m/min). This machine has dual ballscrew drive on the Y and Z axes, and a Meehanite cast iron base for improved rigidity. The expansive work envelope allows for large-part machining.

JTEKT Advantage ROI Justification MACHINE SELECTOR

| Pallet Size | 31.5” x 31.5” (800 mm x 800 mm) |

| Table Index | Full NC table (360,000 positions) |

| X-Axis Travel | 57.1” (1,450 mm) |

| Y-Axis Travel | 49.2” (1,250 mm) |

| Z-Axis Travel | 61” (1,550 mm) |

| Max Workpiece Swing | 59.06” (1,500 mm) |

| Max Workpiece Height | 59.06” (1,500 mm) |

| Maximum Work Load on the Pallet | 5,500 lb (2,500 kg) |

| Spindle Output Torque | 391 ft-lb (530 Nm) |

| Available Spindle | CAT#50 50HP 15,000 RPM (Wide Range 530 Nm) |

| Rapid Feedrate (X axis) | 2,127 ipm (54 m/min) |

| Rapid Feedrate (Y axis) | 2,127 ipm (54 m/min) |

| Rapid Feedrate (Z axis) | 2,127 ipm (54 m/min) |

| Tool Storage Capacity | 60 Standard (121 Optional) |

| Standard Floor Space | 185” x 304" (4,680 mm x 7,710 mm) |

| Machine Height | 145" (3,680 mm) |

| Standard Net Weight | 61,600 lb (28,000 kg) |

| Pallet Size | 31.5” x 31.5” (800 mm x 800 mm) |

| Table Index | Full NC table (360,000 positions) |

| X-Axis Travel | 57.1” (1,450 mm) |

| Y-Axis Travel | 49.2” (1,250 mm) |

| Z-Axis Travel | 61” (1,550 mm) |

| Max Workpiece Swing | 59.06” (1,500 mm) |

| Max Workpiece Height | 59.06” (1,500 mm) |

| Maximum Work Load on the Pallet | 5,500 lb (2,500 kg) |

| Spindle Output Torque | 123 ft-lb (167 Nm) |

| Available Spindle | CAT#50 30HP 15,000 RPM (0-15,000 in 2.6 sec) |

| Rapid Feedrate (X axis) | 2,127 ipm (54 m/min) |

| Rapid Feedrate (Y axis) | 2,127 ipm (54 m/min) |

| Rapid Feedrate (Z axis) | 2,127 ipm (54 m/min) |

| Tool Storage Capacity | 60 Standard (121 Optional) |

| Standard Floor Space | 185” x 304" (4,680 mm x 7,710 mm) |

| Machine Height | 145" (3,680 mm) |

| Standard Net Weight | 61,600 lb (28,000 kg) |

| Pallet Size | 31.5” x 31.5” (800 mm x 800 mm) |

| Table Index | Full NC table (360,000 positions) |

| X-Axis Travel | 57.1” (1,450 mm) |

| Y-Axis Travel | 49.2” (1,250 mm) |

| Z-Axis Travel | 61” (1,550 mm) |

| Max Workpiece Swing | 59.06” (1,500 mm) |

| Max Workpiece Height | 59.06” (1,500 mm) |

| Maximum Work Load on the Pallet | 5,500 lb (2,500 kg) |

| Spindle Output Torque | 744 ft-lb (1,009 Nm) |

| Available Spindle | CAT#50 50HP 8,000 RPM (High Torque 1,009 Nm) |

| Rapid Feedrate (X axis) | 2,127 ipm (54 m/min) |

| Rapid Feedrate (Y axis) | 2,127 ipm (54 m/min) |

| Rapid Feedrate (Z axis) | 2,127 ipm (54 m/min) |

| Tool Storage Capacity | 60 Standard (121 Optional) |

| Standard Floor Space | 185” x 304" (4,680 mm x 7,710 mm) |

| Machine Height | 145" (3,680 mm) |

| Standard Net Weight | 61,600 lb (28,000 kg) |

| Linear Position Accuracy | ± .00012” (.003 mm) full stroke | |

| Linear Repeatability | ± .00006” (.0015 mm) | |

| Rotary Table Index Accuracy | ± 7 arc seconds | |

| Rotary Table Index Repeatability | ± 3.5 arc seconds |

| Hydraulic Oil | Mobil DTE Oil Light (4.75 gal) | |

| Slideway Lubrication | Mobil Vactra #2 (.76 gal) | |

| Spindle Bearing Lubrication | Mobil Velocite #6 (.76 gal) | |

| Spindle Cooling | Mobil Velocite #3 (5.28 gal) | |

| Table Lubrication | Mobil Gear 600 XP 150 (1 gal) | |

| Air Source | 56 ~ 70 psi (4 ~ 5 kgf / cm²) | |

| Power Capacity (Machine Wired: 208V - Transformer Not Included) | 59 kVA |

Specifications are subject to change without notice.

No stranger to JTEKT, CAT upgraded their fleet with new Horizontal Machining Centers.

The FH800SX-i is a powerful, high-speed horizontal machining center.

Pallet Range

21.65" x 21.65" (550 mm x 550 mm)

2,200 lb (1,000 kg) Capacity

Ø2.95" x 20.07" (Ø75mm × 510mm) to

Ø4.72" x 21.45" (Ø120mm × 545mm)

Pallet Range

15.7" sq. (400mm) to 17.7" sq. (450mm)

880 lb (400 kg) Capacity

Ø24.80" x 29.53" (Ø630 mm x 750 mm) to

Ø24.80" x 35.43" (Ø630 mm x 900 mm)

Pallet Range

19.68" sq. (500mm) to 21.65" sq. (550mm)

1,760 lb (800 kg)

Ø31.50" x 39.37" (Ø800 mm x 1,000 mm) to

Ø33.46" x 39.37" (Ø850 mm x 1,000 mm)

Pallet Range

24.8" sq. (630mm)

3,310 lb (1,500 kg)

Ø46.06" x 49.21" (Ø1,170 mm x 1,250 mm)

Pallet Range

31.5" sq (800mm)

5,500 lb (2,500 kg)

Ø39.4" x 25.6" (Ø1,000 mm x 650 mm) to

Ø63" x 51.2" (Ø1,600 mm x 1,300 mm)

Pallet Range

39.4" sq. (1000mm) to 41.3" (1050mm)

6,600 lb (3,000 kg)

Ø70.9" x 63" (Ø1,800 mm x 1,600 mm) to

Ø72.8" x 61" (Ø1,850 mm x 1,550 mm)

Pallet Range

49.2" sq. (1,250mm)

11,000 lb (5,000 kg)

Ø94.5" x 70.9" (Ø2,400 mm x 1,800 mm)

Pallet Range

63" x 49.2" (1,600 mm x 1,250 mm)

17,600 lb (8,000 kg) (Opt. 32,000 lb)

Ø126" x 83" (Ø3,200 mm x 2,100 mm)