RPD: BREATHING NEW LIFE INTO YOUR MACHINES

Às vezes, a melhor e mais econômica maneira de maximizar a produção de seus negócios é reconstruir ou reparar as máquinas que você tem em mãos. Com o apoio de um artesão habilidoso e qualificado, dar uma nova vida ao seu equipamento antigo pode resultar em uma máquina que funciona tão bem quanto, se não melhor, do que quando atingiu o chão de fábrica.

Na RPD, nossa experiência é personalizada para fazer exatamente isso. Reconstruímos e remanufaturamos seus centros de usinagem e retificadoras usados e maltratados - especializados em atender OEMs automotivos e outros fornecedores de peças de alto volume.

Desde a atualização de controles obsoletos, até a adição de um 5º eixo, a engenharia reversa, nossa equipe já viu tudo. Ligue hoje para (847) 253-0340 ou envie um email para nossa equipe em RPD@toyoda.com.

What We Do

Rebuilding:

Subassembly rebuilding is a full or partial reconditioning of the machine that offers a quick turnaround time in bringing your machine back to like-new, OEM condition.

Remanufacturing:

In this complete overhaul of a machine, RPD strips the machine down to the base, where all major castings are steam cleaned, sand blasted, primed, and painted and every machine is thoroughly tested by our engineers before returning to your shop floor.

Retooling & Retrofitting:

RPD also offers newly designed and upgraded tooling, as well as the ability to update hydraulic, pneumatic, or electrical control devices. Our team can also replace your machine’s controls with the latest technology to support your production demands.

Your Team of Machine Experts

We are a collaborative team built of design engineers, journeyman machinists, master builders, and electronic technicians. Well versed in product management, mechanical engineering and design, control, and mechanical refurbishment expertise, some of our crew carry more than 30 years of rebuilding experience. Every member on our trained team stands behind Toyoda’s renowned quality craftsmanship with the engineering, knowledge, and service our customers expect from Toyoda service.

Our Facility

Our 75,000 sq. ft. facility, located in Michigan, has been repairing and rebuilding machines since the late 1970s. RPD is equipped with a climate-controlled inspection room and is capable of custom CNC control systems and controls engineering. Our Global Parts Division has more than 5,500 different replacement parts in stock - capable of sourcing those hard-to-find parts within short lead times.

The Toyoda RPD Difference

With decades of experience in rebuilding and remanufacturing machines, the Toyoda Remanufactured Products Division keeps your business competitive. Our team of professionals has decades of experience bringing machining centers and grinding machines back to OEM specifications - saving you money and time. With the superior craftsmanship and quality service - our customers have the assurance they need that they are making the best decision for their business.

MECHANICAL REBUILD SERVICES

From rebuilds to repairs, and everything in between, our team has the know-how and experience to get your machine running in as-new condition. From CNC control repair to hand scraping, the skilled quality craftsman at RPD have the CNC experience to give you the confidence you need that you are making the most cost-effective decision for your business.

Don't see something listed below? Chances are, our team can do it. Call (847) 253-0340 today or email our team at RPD@toyoda.com.We're here to help.

Services

Preventative Maintenance Procedures

| Inspection of Machine Vee And Flat Ways for wear of turcite or gouging from metal to metal contact | Check Workhead Runout - Tailstock ware of quill to housing | Drain and fill Wheel Spindle fluid with fresh oil |

| Change out Drive Batteries | Way Wipers and Rubbers on both sides of Z axis and clamshell cover of X axis | Replace all external Spindle and hydraulic system filter |

| If applicable, change out MCU and PLC batteries | Check Lubrication system for leaks | Inspect / Replace Wheel Spindle Pulley Belts |

| Confirming Repeatability of All Ballscrews (Backlash) | Clean all Hydraulic tanks and strainer filters replace with new oil | Inspect / Replace Workhead Pulley Belts |

| Check Wheel Spindle (Lift, thrust, and Runout) |

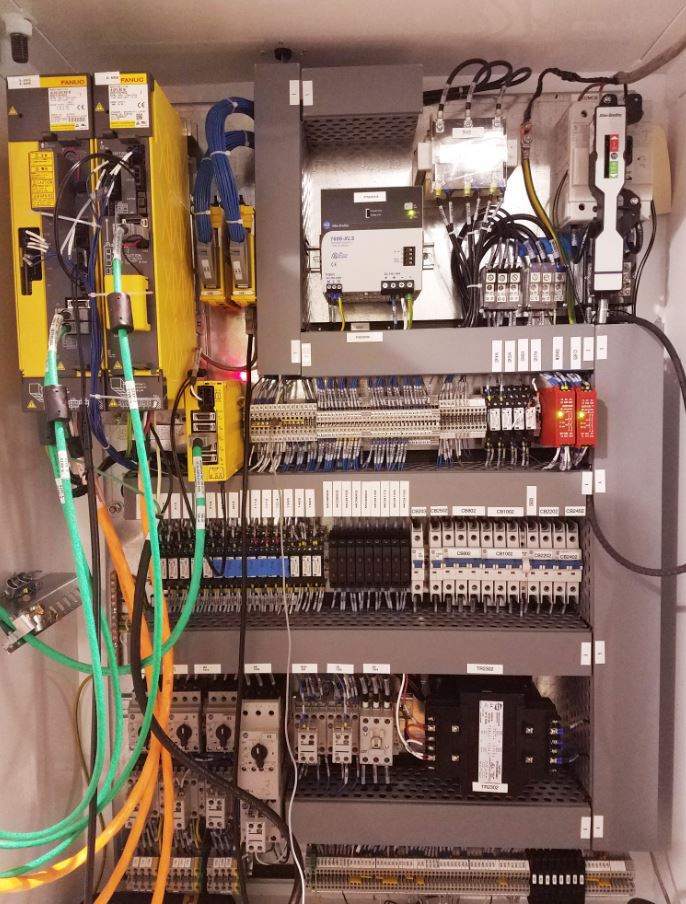

CONTROL RETROFIT

We see the impact of rapidly evolving technology every single day. These technological advancements are particularly evident on a shop floor, where obsolescent control technology can render machines ineffective and inefficient. Today, it is not uncommon for shop floors managers to use machines that mechanically could work much more productively if updated with newer technology capable of supporting features available in newer controls.

Integrating a new retrofitted CNC Control into your machine can increase reliability, decrease future repair costs, increase your lines production capabilities all while leading to shorter cycle times. Trust the engineering experts at RPD, who with over 30 years of CNC experience can get your machine running like new, inside and out.

Our team of qualified machine tool technicians have the knowledge and experience of fully retrofitting Toyoda or FANUC software. From testing to installation, providing new controls or installing new drives and motors, our team has done it all - helping you bring your machine up to today's technological standards.

Toyoda's GC32, GC400, GC500, GC50, GC70 and Fanuc Control with 0i-TF are just a few of the controls our team has worked on. Want to know what we can do for your machine? Call (847) 253-0340

Have an old TOYODA machine that you're looking to part with?

Consider Toyoda's BuyBack Program to sell your machine, trade-in for a completely remanufactured grinding machine from RPD, or apply your trade-in for a new piece of equipment.