In today’s manufacturing environment, automation and machine tools go hand in hand –impacting business performance by providing comprehensive solutions to maximize output and redefine a facility’s current production limitations. In an autonomous facility, whether through robotics, pallet management systems, high capacity tool magazines, or automatic inspection, technology driven solutions give shop owners the ability to get the full value of the line. In addition to fine-tuning machining process, automation increases the line’s working hours and mitigates the industry’s rising deficit of skilled workforce availability.

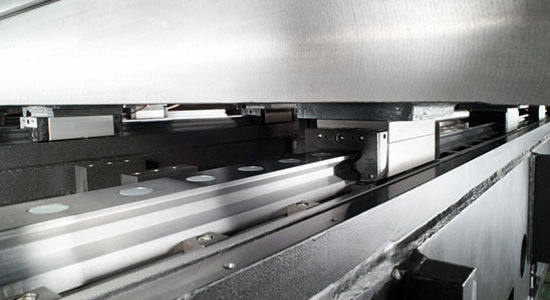

Enhancements like flexible pallet systems (FMS/FPS) use a rail-guided vehicle (RGV) and control software to increase spindle utilization and allow for a significant increase in a shop’s production capacity. Another popular automation solution, robot loading systems, allow machines of various sizes and types to be fully automated. The robots can load parts into a hydraulic fixture and automatically unload the workpiece. These automation solutions allow a facility to substantially increase their unmanned hours or multiply the productivity of skilled operators.

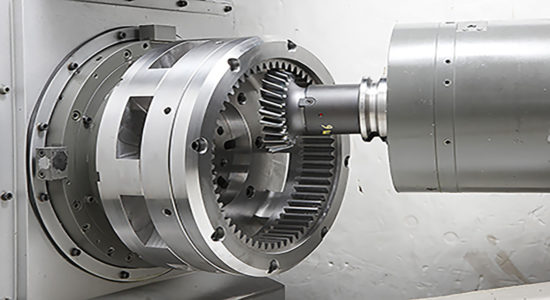

Successful automation comes through a two-fold approach: the strategic use of the right automation technology for your business, working in tandem with CNC equipment built for long-term dependability. Consider that your machine is now running, unmanned, 24/7. The effects of downtime will now have a more severe effect to production. For maximum ROI, work with your machine tool builder to develop the right co-dependent automation/CNC solution.

Connectivity across all platforms in the production system has developed one step further with the industry’s latest trend implementing data driven management techniques. These improve safety, product quality, operational performance & maintenance. This visibility to the entire production line generates a more predictive approach to manufacturing and facilities are better able to conserve energy, eliminate downtime, identify weaknesses and reduce overall production costs. Catch phrases like IoE (Internet of Everything), IIoT (Industrial Internet of Things), Smart Manufacturing and Industry 4.0 all ultimately represent a shop floor’s ability to now have access to production insight – closing machine to machine data gaps.

With a flow of constant data, shop floor managers have the visibility needed to foresee potential breakdowns, bottlenecks, required maintenance, and more importantly, pinpoint room for new revenue opportunities while streamlining their operations. Smaller shops, which typically lack tool management rooms and production engineering departments, are now better able to see the operational status of the facility – leading to shorter cycle times and an optimized production plan. Sensors affixed to a machine can detect sudden stops, instantly alerting shop floors of unexpected downtime, providing the transparency needed to resolve issues much faster. Other IoE technologies allow technicians to review live reports and confidently implement changes to the operation to maximize production and eliminate unexpected costs hindering a strong ROI. See question found in ROI JUSTIFICATION GUIDE: PART 5.

Have additional questions about this portion, reach out to our team today!

Read the next section below: Power Consumption