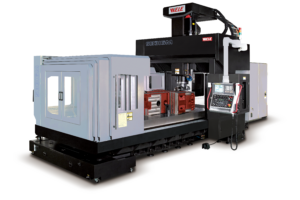

JTEKT Machinery bridge mills and gantry mills provide the power, stability, and durability required in machining large workpieces. This lineup features vibration-dampening Meehanite cast iron bases, effective coolant filtration systems, and fully-equipped Fanuc controls. Additionally, fully programmable five-face machining is available as an option.

JTEKT Advantage ROI Justification MACHINE SELECTOR

Full Line of Bridge Mills and Gantry Mills

VB Series

Job Shop FANUC Oi Double Column Bridge Mill

X-Axis: 79.5" (2,020mm) to 158.2" (4,020mm)

Y-Axis: 59" (1,500mm) to 78.7" (2,000mm)

Z-Axis: 31.5" (800mm)

Spindle: #50 6,000 RPM Geared Head

RB Series

FANUC 31i Double Column Bridge Mill

X-Axis: 83.5" (2,120mm) to 120.5" (3,060mm)

Y-Axis: 47.2" (1,200mm)

Z-Axis: 31.5" (800mm)

Spindle: #50 6K Geared or Highspeed Options

SB Series

FANUC 31i Double Column Bridge Mill

X-Axis: 83.5" (2,120mm) to 159.8" (4,060mm)

Y-Axis: 63" (1,600mm) to 90.5" (2,300mm)

Z-Axis: 31.5" (800mm) to 39.3" (1000mm)

Spindle: Geared Head or Highspeed Options

Five-Face/Right Angle Head Capable

LB Series

FANUC 31i Double Column Bridge Mill

X-Axis: 120.5" (3,060mm) to 253.8" (10,000mm)

Y-Axis: 84.6" (2,150mm) to 157.5" (4,000mm)

Z-Axis: 31.5" (800mm) to 55.1" (1400mm)

Spindle: Geared Head or Highspeed Options

Five-Face/Right Angle Head Capable

LB Series (cont.)

FANUC 31i Double Column Bridge Mill

X-Axis: 120.5" (3,060mm) to 253.8" (10,000mm)

Y-Axis: 84.6" (2,150mm) to 157.5" (4,000mm)

Z-Axis: 31.5" (800mm) to 55.1" (1400mm)

Spindle: Geared Head or Highspeed Options

Five-Face/Right Angle Head Capable

MG Series

FANUC 31i Moving Gantry Mill

X-Axis: 197" (5,000mm) to 787.4" (20,000mm)

Y-Axis: 118.1" (3,000mm) to 236.2" (6,000mm)

Z-Axis: 31.5" (800mm) to 55.1" (1400mm)

Spindle: Geared Head or Highspeed Options

Five-Face/Right Angle Head Capable

MG Series (cont.)

FANUC 31i Moving Gantry Mill

X-Axis: 197" (5,000mm) to 787.4" (20,000mm)

Y-Axis: 118.1" (3,000mm) to 236.2" (6,000mm)

Z-Axis: 31.5" (800mm) to 55.1" (1400mm)

Spindle: Geared Head or Highspeed Options

Five-Face/Right Angle Head Capable