UB-6022D-20

A digital high speed, six head multi-spindle machine designed and popularly used for Printed Circuit Board (PCB) machining. This series is also suited for non-PCB production applications in metals, plastics, etc.

This box type machine base and column are reinforced by inner ribs precisely positioned to increase the damping effect of the machine and increase rigidity. The base and column is a one-piece cast design, aged for four months to stabilize the casting before manufacturing.

This PCB drilling machine features patented NSK pre-tensioned, silent, ball screws installed in order to meet ultra high-speed positioning requirements.

JTEKT Advantage ROI Justification MACHINE SELECTOR

FERROUS SPECS

| Table Size | 29” x 130” (730 x 3,300 mm) |

| Spindle Type | High frequency air bearing spindle |

| # of Spindles | 6 sets |

| Spindle Distance | 22” (550 mm) |

| Spindle Speed | 160,000 / 200,000 RPM |

| Spindle Collet | 1/8" |

| Maximum Working Range | 21.5” x 27” (545 x 690 mm) |

| X,Y-Axis Rapid Positioning Speed | 1,968 ipm (50 m/min) |

| Z-Axis Rapid Positioning Speed | 1,181 ipm (50 m/min) |

| Tool Storage Capacity | 350 bits |

| Machine Dimensions (L x W x H) | 173” x 85.5” x 89” (4,400 x 2,170 x 2,260 mm) |

| Machine Weight | 20,283 lbs (9,200 kg) |

| X,Y-Axis Positioning System | Driven by full digital AC servo motor with linear scale |

| X,Y-Axis Minimum Setting Unit | 0.00004” (0.001 mm) |

| X,Y-Axis Position Accuracy | Full stroke ± 0.0002” (0.005 mm) |

| Z-Axis Positioning System | Driven by its own motor respectively and independently |

| Z-Axis Minimum Setting Unit | 0.00004” (0.001 mm) |

| Z-Axis Feeding Speed | 1~394 ipm (1~9,999 mm/min) |

| Drilling Accuracy | Within ±.0008" (0.02 mm) (ASTRON Condition) |

| Air Clamping | Stack-PIN |

| CNC Controller | S&M CNC 84.00 |

| CPU Specification | 2 GHz |

| Hard Disk | ≧80 GB |

| Memory Volume | 512 MB |

| Interface | USB |

| Operation System | Mouse, Keyboard, LCD Monitor |

NON-FERROUS SPECS

| Table Size | 29” x 130” (730 x 3,300 mm) |

| Spindle Type | High frequency air bearing spindle |

| # of Spindles | 6 sets |

| Spindle Distance | 22” (550 mm) |

| Spindle Speed | 160,000 / 200,000 RPM |

| Spindle Collet | 1/8" |

| Maximum Working Range | 21.5” x 27” (545 x 690 mm) |

| X,Y-Axis Rapid Positioning Speed | 1,968 ipm (50 m/min) |

| Z-Axis Rapid Positioning Speed | 1,181 ipm (50 m/min) |

| Tool Storage Capacity | 350 bits |

| Machine Dimensions (L x W x H) | 173” x 85.5” x 89” (4,400 x 2,170 x 2,260 mm) |

| Machine Weight | 20,283 lbs (9,200 kg) |

| X,Y-Axis Positioning System | Driven by full digital AC servo motor with linear scale |

| X,Y-Axis Minimum Setting Unit | 0.00004” (0.001 mm) |

| X,Y-Axis Position Accuracy | Full stroke ± 0.0002” (0.005 mm) |

| Z-Axis Positioning System | Driven by its own motor respectively and independently |

| Z-Axis Minimum Setting Unit | 0.00004” (0.001 mm) |

| Z-Axis Feeding Speed | 1~394 ipm (1~9,999 mm/min) |

| Drilling Accuracy | Within ±.0008" (0.02 mm) (ASTRON Condition) |

| Air Clamping | Stack-PIN |

| CNC Controller | S&M CNC 84.00 |

| CPU Specification | 2 GHz |

| Hard Disk | ≧80 GB |

| Memory Volume | 512 MB |

| Interface | USB |

| Operation System | Mouse, Keyboard, LCD Monitor |

HIGH TEMP ALLOY SPECS

ACCURACY

| X,Y-Axis Position | Full stroke ± 0.0002” (0.005 mm) |

| Drilling Accuracy | Within ±.0008" (0.02 mm) (ASTRON Condition) |

REEQUIREMENTS

| Total Power Consumption | AC200/220V, 50/60Hz, 20KVA |

| Air Consumption | 237.8 gal/min (900 L/min) |

| Compressed Air Requirements | 99.6-113.8 psi (7-8 kg/cm2) |

| Vacuum Pressure for Chip Collection | 1900 mm-H2O |

| Static Air Pressure for Chip Collection | 4 CMM |

Specifications are subject to change without notice.

Full Line of Vertical Machining Centers

UG Series

X-Axis: 25.1” (640 mm) – 31.5” (800 mm)

Y-Axis: 20.4” (520 mm) – 37.4” (950 mm)

Z-Axis: 18.1” (460 mm) – 25.6” (650 mm)

Spindle: 15,000 RPM or 22,000 RPM

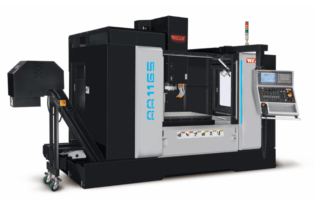

AA-65 Series

Production #40/#50 Taper Boxway

Fully-equipped Standard Fanuc Controls

X-Axis: 35.4" (900 mm) - 59.1" (1.500 mm)

Y-Axis: 25.6" (650 mm)

Z-Axis: 23.6" (600 mm)

Spindle: 6,000 RPM, 8,000 RPM, or 15,000 RPM

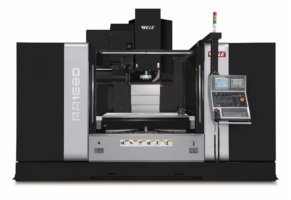

AA-80 Series

Production #50 Taper Boxway

Fully-equipped Standard Fanuc Controls

X-Axis: 55.1" (1,400 mm) - 63" (1,600 mm)

Y-Axis: 31.5" (800 mm)

Z-Axis: 27.6" (700mm) - 31.5" (800 mm)

Spindle: 6,000 RPM Geared or 10,000 RPM DD

AA-80 Series

AA-90 Series

Production #50 Taper Boxway

Fully-equipped Standard Fanuc Controls

X-Axis: 78.7" (2,000 mm)

Y-Axis: 35.4" (900 mm)

Z-Axis: 35.4" (900 mm)

Spindle: 6,000 RPM Geared or 10,000 RPM DD

AA-90 Series

PRO Series

X-Axis Travel: 39.4" (1,000 mm)

Y-Axis Travel: 23.6" (600 mm)

Z-Axis Travel: 23.6" (600 mm)

Spindle: 12,000 RPM

AQ-S Die/Mold

X-Axis: 40.2" (1,020 mm) - 47.2" (1,200 mm)

Y-Axis: 20.1" (510 mm) - 25.6" (650 mm)

Z-Axis: 20.1" (510 mm) - 24.0" (610 mm)

Spindle: 12,000 RPM Direct Drive

AQ-S Die/Mold

AQ Series

X-Axis: 31.5" (800mm) to 63" (1,600mm)

Y-Axis: 20.1" (510mm) to 25.6" (650mm)

Z-Axis: 20.1" (510mm) to 24" (610mm)

Spindle: 15,000 RPM Direct Drive

Integral Pallet Changing Machines

X-Axis Travel: 31.5" (800 mm)

Y-Axis Travel: 17.72" (450 mm)

Z-Axis Travel: 19.7" (500 mm)

Spindle: 12,000 RPM

Integral Pallet Changing Machines

Twin Spindle

X-Axis: 19.7" (500 mm) - 29.5" (750 mm)

Y-Axis: 17.7" (450 mm) - 19.6" (500 mm)

Z-Axis: 18.8" (480 mm) - 23.6" (600 mm)

Drill Tap Centers

The DTC machines are designed for drill tap applications and full milling capabilities.

View Models

PCB Drilling Machines

High speed multi-spindle drilling machines designed for Printed Circuit Board (PCB), metals, plastics, etc.

View Models