Join JTEKT Machinery at IMTS 2024

International Manufacturing Technology Show September 9 -14, 2024 | McCormick Place, Chicago South Building, Level 3 — Metal Removal B…

Carlson Tool & Manufacturing, located in Cedarburg, Wisconsin, purchased their first JTEKT Machinery FA1050S in 2011. The production-focused company wanted to add more capabilities to their tool and contract machining division. After research, price comparisons and a recommendation from a local area shop, Carlson Tool decided JTEKT Machinery was the answer.

After success with their first machine, Carlson continues to expand their fleet with a range of JTEKT Machinery machines to develop their work envelope and increase capacity across the board.

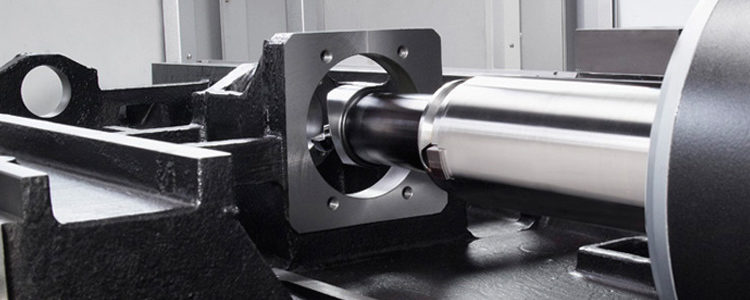

Carlson Tool went with a range of JTEKT Machinery machines to meet their needs. Horizontal machining centers DELIVER UNMATCHED ACCURACY for heavy duty cuts, horizontal boring mills provide JOB FLEXIBILITY, and the five-face bridge mills offer EXCEPTIONAL CAPACITY for large parts.

| FH1250SX Horizontal Machining Center | HB1620 Horizontal Boring Mill | SB316YZM 5-Face Bridge Mill |

| FA1050S Horizontal Machining Center | RB312 (2) Bridge Mills |

30% DECREASE IN PRODUCTION TIME

Carlson Tool has seen a big drop in production times. The introduction of the latest HB1620 has decreased times by 30% compared to their previous horizontal boring mill, from another builder.

FAST DELIVERY

There is no downtime with JTEKT Machinery. Waiting for parts is a thing of the past - and machines are in stock when they want to add a new tool to their arsenal.

100% JTEKT MACHINERY DIVISION

Carlson Tool's contract milling division is now 100% JTEKT Machinery - with plans to replace machines in other divisions with JTEKT Machinery in the future.

CARLSON TOOL APPROVED

Building a JTEKT Machinery fleet has increased the work envelope available and boosted Carlson Tool's business by expanding their range of services. Carlson Tool is fully confident in their capacity to tackle large and difficult jobs.

Download Case Study Sales Sheet

ABOUT CARLSON TOOL & MANUFACTURING

Carlson Tool & Manufacturing is an ISO certified manufacturing company, located in Cedarburg, Wisconsin, serving customers with engineering, tooling, drilling, and machining services. Company website: www.carlsontool.com.

Carlson Tool finds success with the FH1250SX and FA1050S horizontal machining centers, the HB1620 horizontal boring mill, and the RB312 and SB316YZM bridge mills.