Join JTEKT Machinery at IMTS 2024

International Manufacturing Technology Show September 9 -14, 2024 | McCormick Place, Chicago South Building, Level 3 — Metal Removal B…

When it comes time to replace critical equipment, Standridge Color Corporation (SCC) rarely has to worry about late deliveries, faulty components, or shoddy service. That’s because most of the machinery the company uses to produce the color concentrates, compounds, and other plastics-industry products that constitute its core business is manufactured at its in-house machine shop. This strategy gives Bob Standridge, owner and founder of SCC, the flexibility to try out new equipment designs and make alterations without having to deal with outside vendors.

Of course, said Standridge, the primary benefit of in-house production is cost savings, which amount to more than enough to justify the cost of the machining centers used for this work. Although these machines vary by make and model, the company relies primarily on equipment from JTEKT Machinery Americas Corporation for manufacturing its most critical equipment: the twin-screw extruders used to mix various polymers and additives. When asked why he has remained loyal to JTEKT Machinery since installing the first of its machines more than a decade ago, Standridge cites two critical factors: “The first is dependability,” he explained. “Their uptime is better than the other brands we have. The second factor is dimensional stability. It might take three cuts on another machine to remove the same amount of metal as one cut on a JTEKT.”

SCC traces its roots to 1980, when Standridge left a larger firm that performed similar work after recognizing an untapped market in smaller plastic industry manufacturers. The business grew one order at a time, and today, Standridge oversees seven United States plants, as well as one in Europe and one in China. The twin-screw extruders and other equipment used at these locations are produced at the company’s Social Circle, Georgia headquarters. The facility contains a 44,000-square-foot machine shop outfitted with approximately 6 million dollars’ worth of machining and fabricating equipment, including six JTEKT Machinery machines.

The beginnings of this manufacturing operation, however, were much more modest, starting with a few tool room machines to perform repairs in the early 80s. The shop’s first experience with CNC occurred when it retrofitted a large manual lathe to start producing its own extruder screws. It purchased its first true CNC equipment—two VMCs—in 1995.

Those machines served well at SCC, but not in the role for which they originally were intended. Soon after purchasing them, the company realized would need a heavier-duty machine to effectively process certain twin-screw extruder components. “We make some very large parts, and we need machines that are rugged and stable enough to remove more metal per hour than a lighter-duty machine,” Standridge said.

“(JTEKT Machinery's) uptime is better than the other brands we have … It might take three cuts on another machine to remove the same amount of metal as one cut on a JTEKT.”

— Bob Standridge, owner & founder of Standridge Color Corporation

Some gearboxes and barrel assemblies, for example, are cut from blocks that might weigh as much as 5,000 pounds. In addition to being large, most components are made of steel alloys that are difficult to machine even before undergoing heat-treating, nitriding, or chrome-plating operations. Without proper equipment, performing the heavy facing, drilling, boring, and other operations these parts require would be time consuming.

Although SCC doesn’t have the same throughput concerns as a dedicated machine shop might, it still benefits from fast cuts, Standridge said. In 1997, after evaluating models from several different builders, SCC settled on a JTEKT FA630. The company purchased a second FA630 in 1999, and in 2001, it brought in a larger HMC, a FA1050. Success with this equipment led the company to turn again to JTEKT Machinery in 2009, a year when it sought additional manufacturing capacity to replace worn, outdated extruders throughout its facilities worldwide. That round of machine tool purchases included a third FA630 HMC, this one with an upgraded control and other new features; an FV1165, a VMC; and an LB521, a large, bridge mill VMC.

While these machines play different roles in SCC’s manufacturing process, all have proven themselves adept at removing as much material as possible in as few passes as possible, Standridge said. He attributes this to their sturdy construction. “In most cases, these machines weigh about 25 percent more than comparable machines we’ve used from other manufacturers, and most of that weight is in the casting,” he explained.

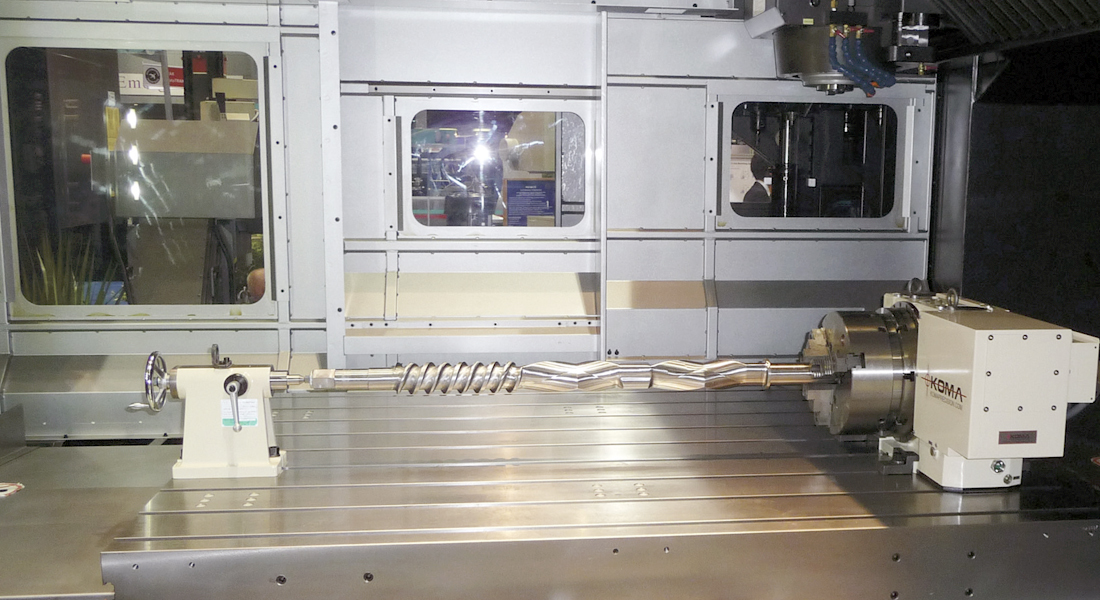

One operation in which this rigidity is on full display is the machining of extruder screws on the LB521. After being turned to size on a lathe, the screws move to this machine’s fourth-axis rotary table for final-geometry machining. While this enables cutting various features in one setup, much of the work requires sufficient dimensional stability to cut away from the part’s axial centerline. “For a long, round piece like an extruder screw, you would normally want to move the tool down directly on top of it, from the 12 o’clock position,” Standridge explained. “But for some of what we want to do, we might move it down at about 2 o’clock. This tends to try to shift that table to one side, but it doesn’t budge.”

The JTEKT Machinery machines not only take heavy, demanding cuts, but do so with very little downtime, Standridge noted. While admitting that SCC doesn’t run its machines nearly as often as most companies that perform metal cutting as their primary business, he points out that the JTEKT Machinery machines require noticeably less maintenance than other models employed at the in-house machine shop. The shop’s first machines from this builder—the two FA630s purchased in the late 90s—are a case in point, he said of the one electrical issue the machine had in more than a decade of operation.

The JTEKT Machinery spindles stand up especially well compared to other machine brands on the shop floor, Standridge said, adding that other machines require relatively frequent attention for problems with bearings, drive belts, and other spindle-assembly components. And if one of the JTEKT Machinery's were to experience a spindle issue, it would be easier to fix because JTEKT Machinery's horizontal machining centers have removable spindle tapers, he notes. Instead of replacing a costly spindle, the spindle taper can be quickly switched out, allowing shops to resume production.

Standridge also observed that other machines had leaky through-spindle coolant systems, typically a culprit of heat from the cut causing a coolant-through cutting tool to expand. This is especially problematic when the coolant eats into the spindle drive belt, an issue that requires “taking the machine half apart” to fix, he said. In contrast, the JTEKT Machinery machines employ direct-drive or directly gear-driven spindles rather than belts, and they feature a refrigeration system that prevents tools from expanding in this way.

The nature of SCC’s in-house machining work doesn’t require particularly high part volumes, tight tolerances or short turnaround times. Nonetheless, the JTEKT Machinery machines’ reliability and stability ensure that the company can reap the benefits of in-house production without distractions. As a result, SCC will likely consider JTEKT Machinery when it seeks to add to its machining capabilities—a scenario that is virtually guaranteed as the company continues to incorporate new developments in extruder technology and moves to replace worn equipment, Standridge said.