Join JTEKT Machinery at IMTS 2024

International Manufacturing Technology Show September 9 -14, 2024 | McCormick Place, Chicago South Building, Level 3 — Metal Removal B…

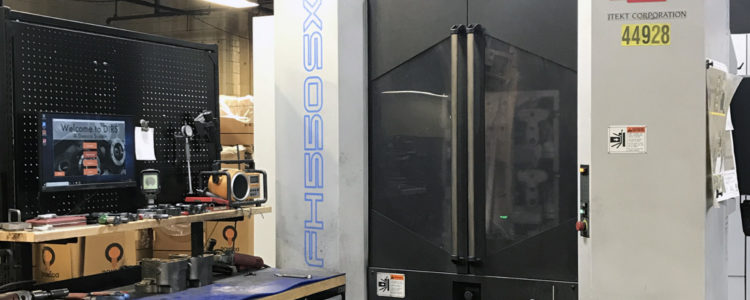

Donsco purchased their first two JTEKT Machinery FH55 horizontal milling machines in 1985 and quickly followed with three more. The first five JTEKT Machinery machines on the shop floor were installed within 5 years—a quick transition from manual labor to machining to keep with customer demand.

Today, Donsco is North America’s leading single-source provider of machined iron castings. As Donsco continues to secure customers requesting difficult work with tighter tolerances, they are taking the older machines offline and upgrading to the latest generation of JTEKT Machinery. Machining steel and cast iron 24 hours a day, 6 days a week requires equipment you can rely on—and after 30 years, they know that is JTEKT Machinery.

To tackle the new work coming in, Donsco added a new generation of JTEKT Machinery machines to deliver EFFICIENT and HIGH-PRECISION MACHINING. JTEKT Machinery horizontal machining centers provide industry-leading SPEED, RIGIDITY and ACCURACY that withstand the test of time.

OUTCOME

30% INCREASE IN THROUGHPUT

Not only were the new machines faster, but they were more accurate with less variation than the older models.

INCREASED CAPACITY

While the older machines were still running, the new machines increased capacity with faster cycle times.

REDUCED MAINTENANCE COSTS

Donsco’s upgrade saves on maintenance costs as well. The total cost of ownership was a key factor in their decision to stick with JTEKT Machinery.

NEW HEAVY MANUFACTURING CUSTOMERS

When customers like Caterpillar, Mack Truck, Permco and Case New Holland tour Donsco’s shop and see 14 JTEKT Machinery machines, they understand the investment and commitment they put into their work.

ABOUT DONSCO, INC.

Donsco is North America's leading single source provider of machined iron castings and has been in continuous operation for more than 100 years.

https://donsco.com/