For a variety of machining needs, including high-speed, heavy-duty, and 5-axis machining, JTEKT Machinery’s complete line of vertical machining centers delivers lasting performance. Due to a vibration-dampening Meehanite cast iron base and large precision spindle bearings, we offer shops increased rigidity while sustaining higher load capacities. Every vertical machining center features fully-equipped Fanuc controls for maximum machining capabilities.

JTEKT Advantage ROI Justification MACHINE SELECTOR

Full Line of Vertical Machining Centers

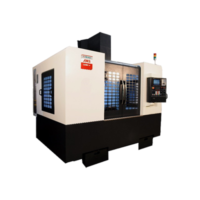

UG Series

X-Axis: 25.1” (640 mm) – 31.5” (800 mm)

Y-Axis: 20.4” (520 mm) – 37.4” (950 mm)

Z-Axis: 18.1” (460 mm) – 25.6” (650 mm)

Spindle: 15,000 RPM or 22,000 RPM

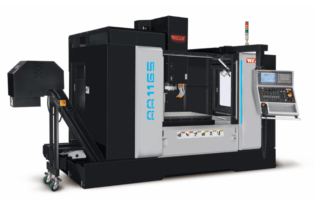

AA-65 Series

Production #40/#50 Taper Boxway

Fully-equipped Standard Fanuc Controls

X-Axis: 35.4" (900 mm) - 59.1" (1.500 mm)

Y-Axis: 25.6" (650 mm)

Z-Axis: 23.6" (600 mm)

Spindle: 6,000 RPM, 8,000 RPM, or 15,000 RPM

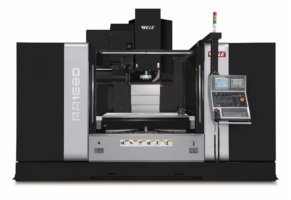

AA-80 Series

Production #50 Taper Boxway

Fully-equipped Standard Fanuc Controls

X-Axis: 55.1" (1,400 mm) - 63" (1,600 mm)

Y-Axis: 31.5" (800 mm)

Z-Axis: 27.6" (700mm) - 31.5" (800 mm)

Spindle: 6,000 RPM Geared or 10,000 RPM DD

AA-80 Series

AA-90 Series

Production #50 Taper Boxway

Fully-equipped Standard Fanuc Controls

X-Axis: 78.7" (2,000 mm)

Y-Axis: 35.4" (900 mm)

Z-Axis: 35.4" (900 mm)

Spindle: 6,000 RPM Geared or 10,000 RPM DD

AA-90 Series

PRO Series

X-Axis Travel: 39.4" (1,000 mm)

Y-Axis Travel: 23.6" (600 mm)

Z-Axis Travel: 23.6" (600 mm)

Spindle: 12,000 RPM

AQ-S Die/Mold

X-Axis: 40.2" (1,020 mm) - 47.2" (1,200 mm)

Y-Axis: 20.1" (510 mm) - 25.6" (650 mm)

Z-Axis: 20.1" (510 mm) - 24.0" (610 mm)

Spindle: 12,000 RPM Direct Drive

AQ-S Die/Mold

AQ Series

X-Axis: 31.5" (800mm) to 63" (1,600mm)

Y-Axis: 20.1" (510mm) to 25.6" (650mm)

Z-Axis: 20.1" (510mm) to 24" (610mm)

Spindle: 15,000 RPM Direct Drive

Integral Pallet Changing Machines

X-Axis Travel: 31.5" (800 mm)

Y-Axis Travel: 17.72" (450 mm)

Z-Axis Travel: 19.7" (500 mm)

Spindle: 12,000 RPM

Integral Pallet Changing Machines

Twin Spindle

X-Axis: 19.7" (500 mm) - 29.5" (750 mm)

Y-Axis: 17.7" (450 mm) - 19.6" (500 mm)

Z-Axis: 18.8" (480 mm) - 23.6" (600 mm)

Drill Tap Centers

The DTC machines are designed for drill tap applications and full milling capabilities.

View Models

PCB Drilling Machines

High speed multi-spindle drilling machines designed for Printed Circuit Board (PCB), metals, plastics, etc.

View Models